In today’s world of just in time manufacturing models, clients demand printed products in very short turnaround times. At CCS Packaging, we have built our business and systems to be able to facilitate industry leading turnaround times.

There are some simple yet important steps that clients can undertake when supplying files to ensure we are able to deliver expected results in ultra fast times.

The biggest area that steals time from print order to delivery is during the file approval process, when we need to make changes or conversions to create a press-ready file.

For the most part, we can convert files from RGB to CMYK (4 Process), we can convert fonts to outlines , adjust trapping , extract knifelines etc., but by doing so we are altering the source file.

When the altered file is converted to a press ready version , we submit this back to the client. This is when the RGB to CMYK conversions may not reflect what the client expected, or the font outlined presents differently due to the low resolution preview, even though it will print perfectly.

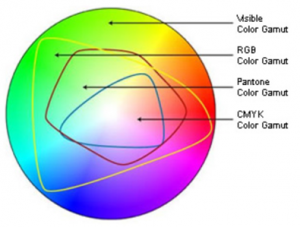

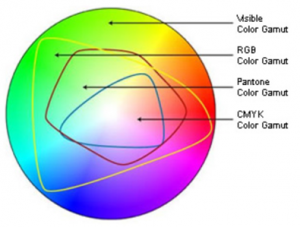

Converting RGB to CMYK can yield unexpected results especially when converting RGB colours that cannot be replicated using process printing

We convert RGB to CMYK regularly and within the process offset printing gamut, this generally poses no problems. Anomalies can emerge when colours are used that are beyond what can be achieved using 4 colour process, such as Pantone colours. Pantone colours may achieve colours that are not reproducible using process inks and, ultimately, an RGB screen will always have a larger colour gamut than is producible using modern print processes.

This chart is an example of the greater gamut of colours that RGB can produce over CMYK printing. When converting colours outside of the CMYK gamut is where unexpected result may be generated.

These anomalies usually create questions and back and forth conversations relating to the conversion.

The client may want to make changes to the colour to achieve what they had in mind, which means a trip back to the art studio, all the while eating into production time.

The solution for this would be to supply press ready files that don’t need conversions. This will allow the client to have a closer understanding of what the press output will look like and the chance of unexpected results are eliminated as we are all working from the same unadulterated source file.

To create press-ready files, we would recommend your art design agency supplies files that meet the below criteria.

BASIC FILE ATTRIBUTES ACHIEVE EXPECTED IMAGE RESULTS

1. PDF create via export from Adobe applications

2. No security restrictions to be applied ü

3. No trapping to be applied

4. All images should exceed 300 DPI

5. All logos (bitmaps) should be at least 1200DPI

6. Hairlines must not be used. Minimum line width is 0.1mm for positive lines and 0.15mm for negative lines ü7. Fonts - 5pt for positive or larger, and 6pt or larger for negative 8. Files to be set up for CMYK print – RGB is not advisable

Low res never looks good

Low res never looks good

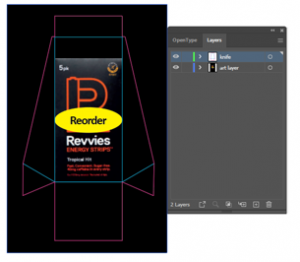

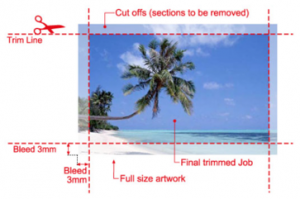

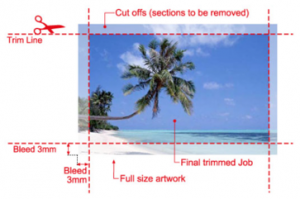

PREFERABLE FILE GEOMETRY SETTINGS

1. The PDF must contain a trim box

2. The trim box must be set to the correct size

3. The trim box must be in the corrected position

4. Trim marks must align with trim box

5. A minimum of 3mm bleed must be present additional to the trim box boundary ü15. All files must be set to 100% scale

Ensuring bleed is present will prevent white lines appearing on the trimmed edge of the sheet.

Ensuring bleed is present will prevent white lines appearing on the trimmed edge of the sheet.

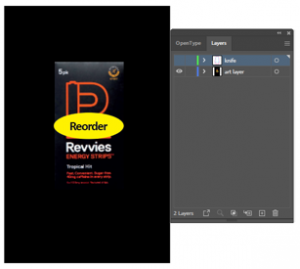

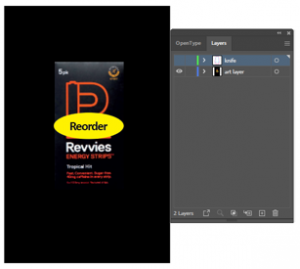

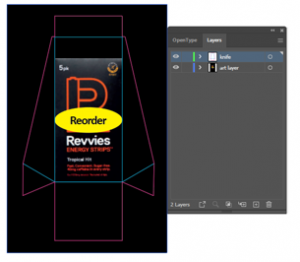

KNIFELINE AND EMBELLISHMENT SETTINGS

ü16. Knife lines should be on their own layer and set to Overprint, not Knockout. Cut and crease must be clearly defined ü17. All special finishes, such as SPOT UV, EMBOSS should be on separate pages and set to overprint ü18. Special PMS colours to be converted to CMYK unless print has been ordered specifying special PMS colours

What if I cannot supply art files to the above criteria?

Ultimately, it is not the end of the world. Our skilled team of prepress operatives can make the required adjustments and assist you to achieve your desired outcome. Your design studio should be able to meet the criteria also.

We are always happy to help, but if the file is press-ready at the start, it expedites print turn around times

Low res never looks good

Ensuring bleed is present will prevent white lines appearing on the trimmed edge of the sheet.

Ensuring bleed is present will prevent white lines appearing on the trimmed edge of the sheet.